In a world where sustainability has become a pressing concern,…

Transforming the Supply Chain With Additive Manufacturing

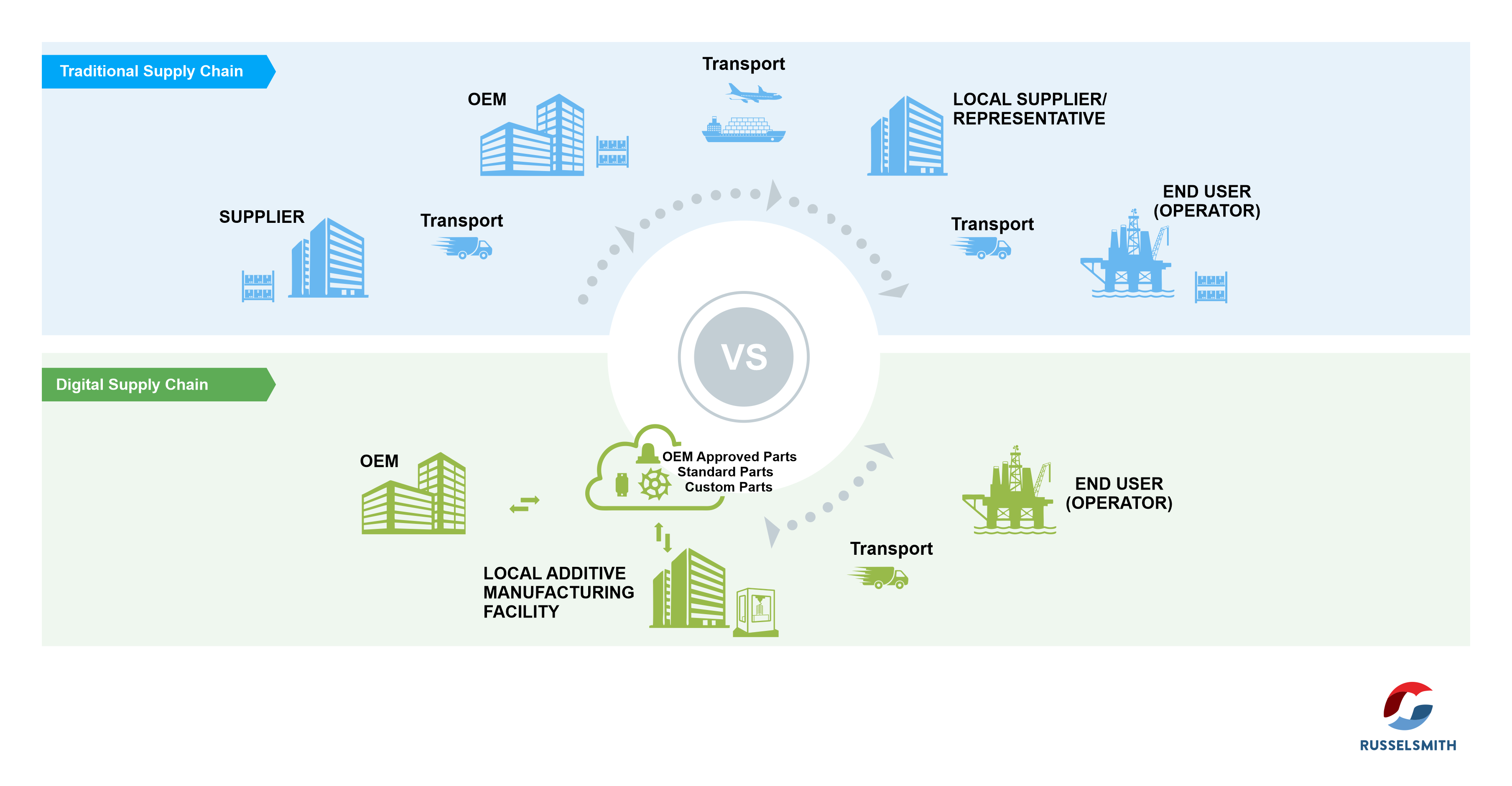

In an era marked by the rapid adoption of transformative technologies across various domains, the landscape of manufacturing and product distribution is evolving significantly. Additive manufacturing, commonly known as 3D printing, has emerged as a disruptive force with the potential to revolutionize supply chains and redefine the principles of supply chain management across diverse industries.

Conventional supply chains have historically grappled with vulnerabilities stemming from challenges such as trade conflicts, natural disasters, economic fluctuations, increasing transportation costs, and other bottlenecks like port congestion, inadequate infrastructure, inconsistent policies, and warehousing deficiencies.

The resilience of a supply chain system plays a pivotal role in the operational performance of a company. An effective supply chain system translates to heightened efficiency, superior quality control, enhanced customer satisfaction, accelerated production cycles, reduced production costs, and an overall enhancement in a company’s financial performance.

To mitigate the impact of common supply chain disruptions on business operations, companies must embrace technological advancements that simplify and improve the efficiency of supply chain processes.

Fortunately, additive manufacturing technology offers a way to significantly optimize traditional supply chain processes through digital warehousing and on-demand manufacturing of parts. By harnessing additive manufacturing technology, companies can manufacture industrial parts near their end-users, effectively diminishing lead times and reducing the need for complex transportation and its associated carbon emissions, while reducing the need to maintain large inventory volumes.

Benefits of Additive Manufacturing to the Supply Chain

- Enables on-demand manufacturing close to the end users, with minimal delivery lead times and no need for minimum order quantities.

- Reduces the costs associated with physical warehousing and stockpiling.

- Reduces reliance on foreign manufacturing and costly shipping expenses.

- Additive manufacturing allows for the design and production of intricate components using industrial 3D printing techniques that are faster than traditional manufacturing processes, and with more flexibility in materials.

- Facilitates rapid prototyping, enabling quick assessments of factors like usability, material suitability, and manufacturability to optimize the manufacturing process.

- Improves sustainability in supply chain operations. By manufacturing locally and in the required amounts through additive manufacturing, companies are able to reduce their environmental footprints and manage resources better.

Additive manufacturing stands as a game-changer in supply chain management, offering innovative solutions to age-old challenges. As the business world continues to evolve, the need for resilient supply chains becomes more critical than ever, and companies that embrace additive manufacturing will be well-positioned to not only weather supply chain storms more effectively but also to unlock new opportunities for innovation, customization, and customer satisfaction.

To learn more about our additive manufacturing services, visit https://russelsmithgroup.com/smart-manufacturing