A solution for rapid inspection of buried pipelines without contact, especially when such pipelines are considered unpiggable.

The innovative and field-tested Non-Contact Magnetometry (NCM) method from RusselSmith is the ideal solution for inspecting buried pipes. It was developed in response to the challenges faced by operators when inspecting such pipelines.

NCM is a non-intrusive or non-contact method for inspection of steel pipelines – even when such pipelines are buried, without requiring de-burial of the pipes.

It works by identifying changes along a pipeline’s magnetic field which are caused by stress, tension or corrosion. The received data is visualized in real time and shows the locations of anomalies along the pipe, complete with GPS coordinates.

NCM inspections can identify anomalies which are caused by the following types of problems on pipelines:

- Metal Loss

- Crack-like Defects

- Pipeline Geometry Changes (loss of stability)

- Stress-strained Condition

- Mechanical Damage

- Weld Anomalies

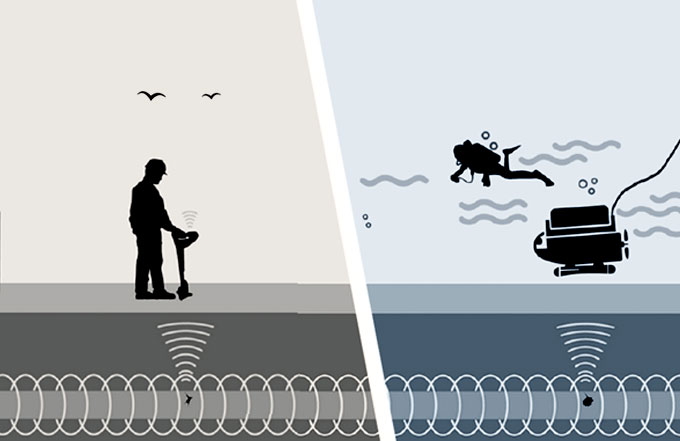

NCM can easily be deployed onshore and can also be deployed subsea by a diver or mounted on an ROV. The device is lightweight and is rated for a water depth of 2000m.

Subscribe to our newsletter, for company updates, industry and technology news and much more.