In an era marked by the rapid adoption of transformative…

Discover Four Ways in Which Additive Manufacturing is Driving Sustainability

In a world where sustainability has become a pressing concern, businesses are constantly seeking new ways to reduce their environmental footprints. One promising solution to this sustainability challenge is the adoption of additive manufacturing.

Additive manufacturing, also known as 3D printing, is an innovative technology that is already transforming the way goods are manufactured around the world, and is gaining relevance as way to boost sustainability efforts in the manufacturing process. It involves using industrial 3D printing processes to manufacture functional components, including production-ready parts and tooling, usually by adding layer upon layer of material until the final product is formed.

As additive manufacturing technology continues to evolve, more efficient materials and procedures are being introduced, making it a more efficient and more environmentally friendly alternative to many traditional manufacturing methods.

Here are four ways in which additive manufacturing improves sustainability:

- Minimizing Material Waste

One of the most compelling aspects of additive manufacturing is its ability to minimize material waste. Traditional manufacturing generally makes use of subtractive processes, such as starting with a block of material and removing excess material to form the final product. This results in a significant amount of waste. In contrast, additive manufacturing produces required parts by building the objects layer by layer, only using the precise amount of material that is needed. This reduction in waste is an important step towards a more sustainable future. - Energy Efficiency

Additive manufacturing is inherently more energy-efficient than traditional manufacturing methods, especially when it comes to small-scale and customized manufacturing. In these cases, energy consumption is significantly lower due to the absence of the energy-intensive setup and tooling processes required in traditional manufacturing. - Recycling of Materials

Additive manufacturers are able to recycle waste by converting out-of-specification products from their operations to raw materials which can then be used to produce more products. - Lower Emissions Due to Local Production and Supply Chain Optimization

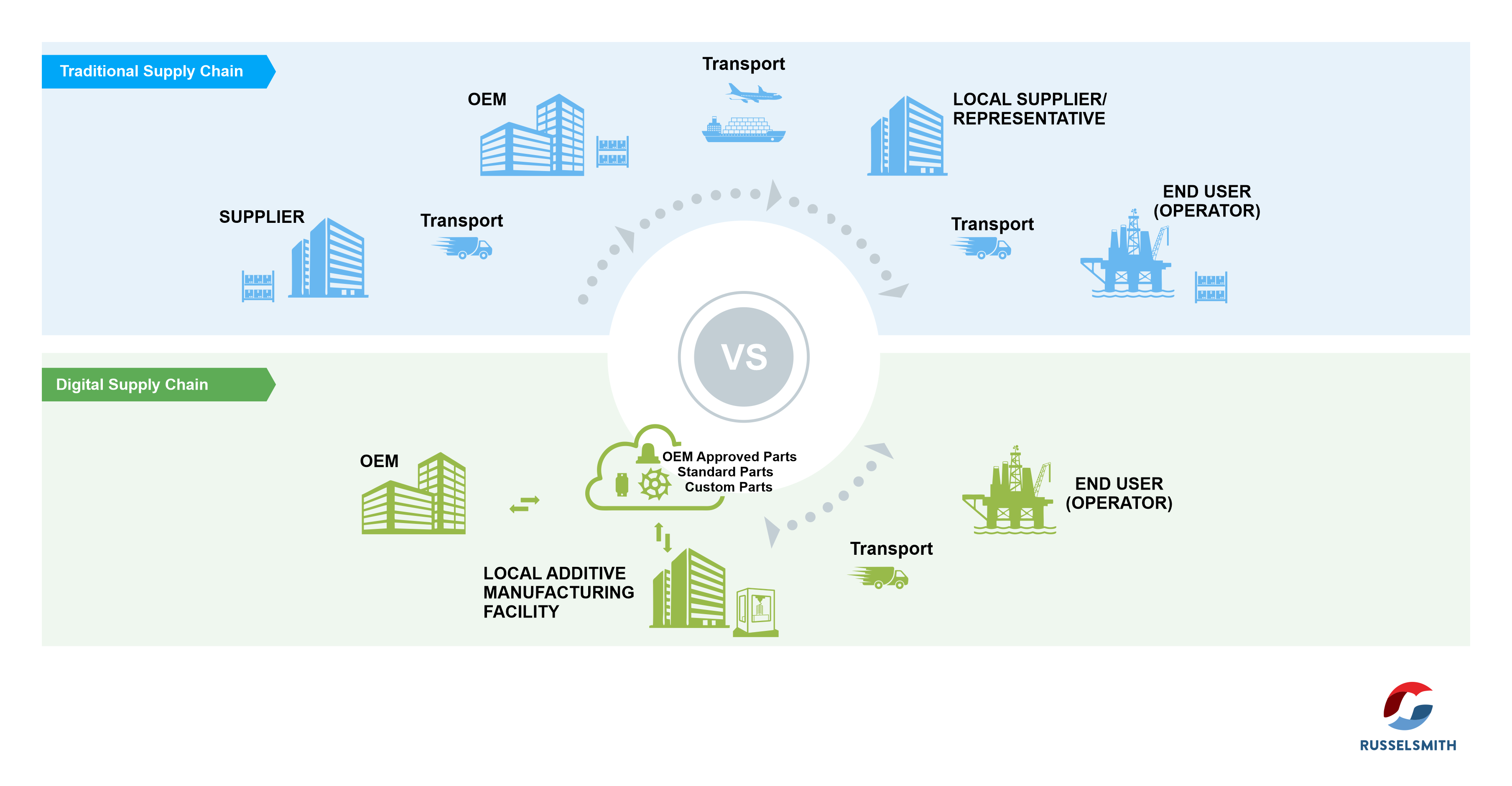

Additive manufacturing has the potential to revolutionize the traditional supply chain model. By enabling local production in close proximity to consumers, the need for long and complex supply chains is reduced. This leads to a significant decrease in transportation-related emissions and more efficient distribution of goods.

The Future of Manufacturing is Local, On Demand, and More Sustainable

With increased adoption and accessibility, additive manufacturing holds the potential to transform diverse industries and help to make them more environmentally sustainable, operationally efficient, and ecologically friendly. Whether applied in energy, aerospace, healthcare, automotive, or consumer goods, additive manufacturing stands out as a crucial instrument in our collective endeavour to achieve a more sustainable future.

To learn more about RusselSmith’s additive manufacturing solutions, visit https://russelsmithgroup.com/smart-manufacturing