From Leaks to Reliability: Additive Manufacturing of a Replacement Bag Filter Housing for Offshore Desalination

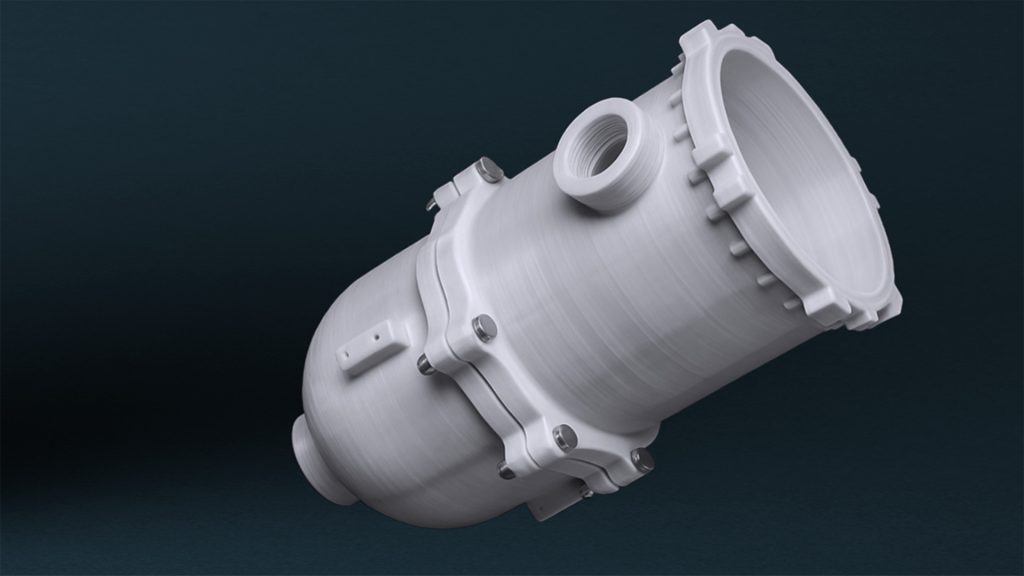

Cracks, joint failures, and persistent leaks in a UPVC filter bag housing were putting an offshore desalination system at risk, compromising water quality and causing costly downtime. When approached for a solution, we developed a more robust alternative housing design, manufactured using ULTEM 9085 and the Fused Filament Fabrication (FFF) additive manufacturing method. The new design reduced the number of joints, improved structural integrity, and stabilized flow dynamics—delivering a leak-proof solution that was well-suited to withstand the operational demands of its intended environment.

This project demonstrates how additive manufacturing can do more than just replace worn-out legacy parts. It enables performance-driven design improvements, reduces lead times, and improves sustainability. By manufacturing locally and eliminating the need for costly retooling of injection molding equipment, we reduced waste and carbon footprint while extending the component’s service life, thus supporting more resilient and sustainable offshore operations.